china high head submersible slurry pump

Latest articles

The frame plate for WAJ series pumps has interchangeable hard metal or pressure moulded elastomer liners. The impellers are made of pressure moulded elastomer liners.The shaft seals for WAJ series can be packing seal, centrifugal seal or mechanical seal.

china high head submersible slurry pump...

china high head submersible slurry pump 【china high head submersible slurry pump】

Read MoreConsider the following.

china high head submersible slurry pump...

china high head submersible slurry pump 【china high head submersible slurry pump】

Read MoreVertical Slurry Pump

china high head submersible slurry pump...

china high head submersible slurry pump 【china high head submersible slurry pump】

Read MoreSlurry pipe diameter.

china high head submersible slurry pump...

china high head submersible slurry pump 【china high head submersible slurry pump】

Read MoreExamples of these dubious enhancements to impeller adjustment abound in the industry. One of these is the adjustable wear ring or suction liner to maintain the recommended clearance between the impeller front shroud and the throat bushing face. Almost all >slurry pumps, including AIER® slurry pumps, have features to ensure that this equipment specification can be maintained over time.

china high head submersible slurry pump...

china high head submersible slurry pump 【china high head submersible slurry pump】

Read MoreA dredge pump contains a pump casing and an impeller. The impeller is mounted in the pump casing and connected to the drive motor via a gearbox and shaft. The front part of the pump casing is sealed with a suction cover and connected directly to the suction pipe of the dredger. The discharge port of the dredge pump is located near the top of the dredge pump and is connected to a separate discharge line.

china high head submersible slurry pump...

china high head submersible slurry pump 【china high head submersible slurry pump】

Read MoreThe dredge pump is designed to draw sediment, debris and other hazardous materials from the surface layer into the suction pipe and transport the material through the pipe to the discharge site. The pump must be able to handle common solid debris of various sizes that can pass through the pump, thus minimizing the downtime required for cleaning.

china high head submersible slurry pump...

china high head submersible slurry pump 【china high head submersible slurry pump】

Read Morehow-does-a-dredge-pump-work

china high head submersible slurry pump...

china high head submersible slurry pump 【china high head submersible slurry pump】

Read MoreTo reduce component wear, most centrifugal slurry pumps run at fairly low speeds - typically less than 1200 rpm. Find the optimum position that allows the pump to run as slowly as possible but fast enough to prevent solids from settling out of the slurry deposit and clogging the lines.

china high head submersible slurry pump...

china high head submersible slurry pump 【china high head submersible slurry pump】

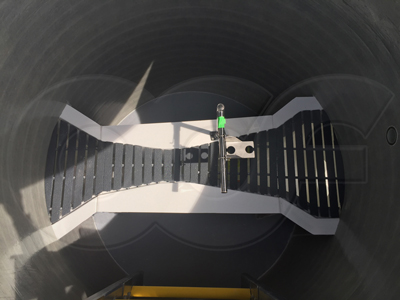

Read MoreDischarge ports can be placed at 45 degree intervals and oriented in up to 8 different positions depending on your needs.

china high head submersible slurry pump...

china high head submersible slurry pump 【china high head submersible slurry pump】

Read More

Popular articles

Latest articles

-

If you want to get more information about the best slurry pump, welcome to >contact us today or request a quote.

-

A >dredge pump is a horizontal centrifugal pump that is the heart of a dredger. It is designed to handle suspended abrasive granular materials and solids of limited size. Without a dredge pump, a stranded dredger would not be able to deliver mud.

-

How does a dredge pump work?

-

Slurry pump design

-

Horizontal centrifugal pumps are commonly used for slurry service, but vertical and other types of pumps are better suited to certain specific applications. Centrifugal pumps for handling slurries have features tailored to specific services that reflect the corrosive or abrasive nature of the slurry and the concentration of solids. These may include the choice of materials, the use of liners or even different drive sizes.

-

Choosing Dry Slurry Pumps Versus Submersible Slurry Pumps

Links

- Customization extends beyond material selection to include the shaping and forming of the FRP

- In conclusion, fiberglass customized products are revolutionizing various industries by providing solutions that cater to specific needs, enhancing performance, and offering cost-effective alternatives. As the demand for personalized products continues to grow, the use of fiberglass in customized applications is expected to increase, further driving innovation and growth in related sectors.

- When choosing a drill bit for your next project, be sure to consider the shank type that will work best for your specific needs. Whether you need a versatile straight shank, a high-torque hex shank, or a durable taper shank, selecting the right shank can make all the difference in the success of your drilling tasks. With the wide range of shank types available, you can find the perfect bit for any job.

- Powered by a robust motor, the YT27 delivers a forceful impact that can penetrate deep into solid rock with remarkable speed. Its efficient design allows for minimal vibration, enhancing operator comfort and increasing overall productivity. The drill's ergonomic handle and well-balanced weight distribution ensure ease of use, reducing fatigue during extended work shifts.

For example, softer rock formations may benefit from bits with larger cutting structures, while harder rock formations may require smaller, more aggressive cutters For example, softer rock formations may benefit from bits with larger cutting structures, while harder rock formations may require smaller, more aggressive cutters

For example, softer rock formations may benefit from bits with larger cutting structures, while harder rock formations may require smaller, more aggressive cutters For example, softer rock formations may benefit from bits with larger cutting structures, while harder rock formations may require smaller, more aggressive cutters

Additionally, they have a long service life, reducing the need for frequent replacements and thus, lowering maintenance costs Additionally, they have a long service life, reducing the need for frequent replacements and thus, lowering maintenance costs

Additionally, they have a long service life, reducing the need for frequent replacements and thus, lowering maintenance costs Additionally, they have a long service life, reducing the need for frequent replacements and thus, lowering maintenance costs

With accurate measurements and control, they can produce consistent tapers with remarkable accuracy, ensuring a perfect fit between components With accurate measurements and control, they can produce consistent tapers with remarkable accuracy, ensuring a perfect fit between components

With accurate measurements and control, they can produce consistent tapers with remarkable accuracy, ensuring a perfect fit between components With accurate measurements and control, they can produce consistent tapers with remarkable accuracy, ensuring a perfect fit between components